Grinding involves utilizing technology designed for this purpose. Grinding workpieces requires employing the right tools. Essentially, the equipment consists of an abrasive wheel to remove small parts of the workpiece. This piece of machinery is the grinder. Depending upon the requirements, it can be one of the different styles including cylindrical grinding.

The Purpose of Grinding

The intent of grinding a workpiece is to remove any excess material on its surface. Grinding is a finishing process. It reduces the roughness of the surface and, therefore, improves its quality. This process is common in a variety of industrial operations including:

* Automobile manufacturing

* Electrical concerns

* Engineering facilities

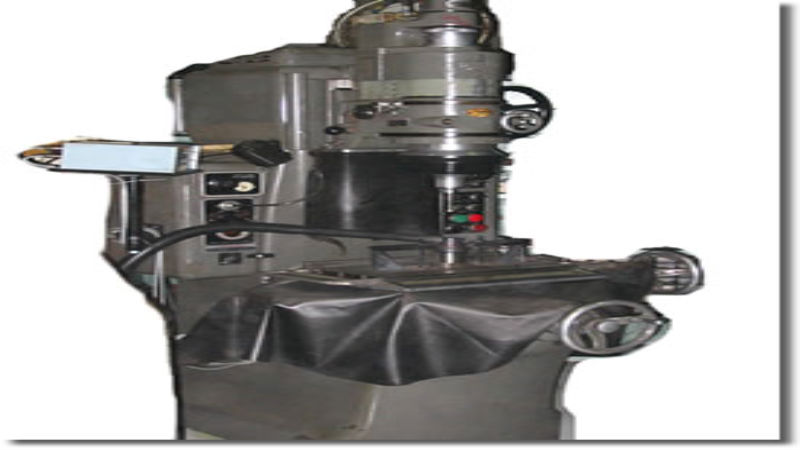

Cylindrical grinders – often machinery having many grinding wheels, find application in honing cylindrical parts. Grinding companies will select the specific type of cylindrical grinder depending upon the specific needs and application. When it comes to cylindrical grinding, the decision to choose this technique has as its basis, the need for high accuracy and precision.

Types of Cylindrical Grinders

Cylinder grinders fall essentially into two types. These are

1. Center grinders: These generally are applicable when the need is to grind plain cylindrical components

2. Centerless grinders: This method does not clamp the workpiece in place. Instead, it lies between two parts: the regulating wheel and the grinding wheel

Subdivisions of these types include

* Outside Diameter (OD) Grinding: This is a centerless grinding machine process

* Inside Diameter (ID) Grinding:

* Plunge Grinding

* Creep Feed Grinding

These variations allow grinders to offer a variety of surfaces within the basic types of grinding services.

Cylindrical Grinding

When it comes to producing precise forms, it is hard to beat cylindrical grinders. In the manufacturing of bearings, bushings, rods, and tubes, companies rely on grinding companies to finish their products to a high degree of accuracy with tight tolerances. Cylindrical grinding machines are capable of meeting these demands.