Aluminum extrusion companies are helpful when you need to produce an aluminum shape that has a constant cross-section. The extrusion process offers several advantages over other types of manufacturing processes, and aluminum is a popular material to use in the process due to its many valuable qualities. With the assistance of a qualified company, you can efficiently create products that are perfect for your unique applications.

Shape-related Benefits

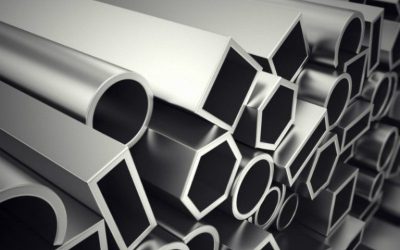

One of the biggest advantages of the aluminum extrusion process is that the company you select can create a large number of shapes, even those that are more complex. Shapes with irregular surfaces and light gauge walls can be challenging to cut, but experienced aluminum extrusion companies can easily cut these types of extrusions for you using the appropriate precision sawing equipment. The right equipment will allow cuts to be made to extremely precise tolerances.

Lifetime Benefits

You’ll also find that aluminum extrusions will last a long time. Aluminum is often viewed as flimsy material because the word “aluminum” often brings to mind images of aluminum foil or soda cans in people’s minds. In reality, aluminum is a highly durable material that won’t break down for a long time. Once your extrusions are in the proper place, you can depend on them to serve their intended purpose long term without requiring replacement.

Aluminum Benefits

The aluminum extrusion process will yield for you a strong part that has a low density – an attractive characteristic of the metal. Aluminum’s density is about a third of that of steel. Aluminum is also an excellent material to use in the extrusion process because it is corrosion resistant; it naturally has a transparent, thin oxide film that protects it.

Experts can additionally machine aluminum at a speed of between 600 to 700 surfaces a minute, with special tools and lubricants available to allow for even higher machining speeds. You can also join aluminum alloys by soldering, brazing, and welding. Finally, shapes that are extruded can be bent or formed with conventional equipment, so the process is convenient and will help you to get the results you need and expect promptly.