When it comes to electrical current or power transmission and distribution across a system, bus bar is a common option. In the past bus bar was often made of copper or brass, but electrical grade aluminum bus bar is now seen as a more cost-effective option for a wide range of different applications.

It is possible to find electrical grade aluminum bus bar in different parts or applications within any type of electrical power distribution systems. This can include in a power substation, within an electrical component or as used to transfer power from a battery bank.

There is an advantage to using bus bar over wiring, particularly for short distances. It is lightweight and can be designed to have a greater surface area, which in turn allows higher rates of electrical current transfer. Consider the difference in surface area over a wire and a flat strip or plate and it is easy to see why this is a superior choice.

The Design

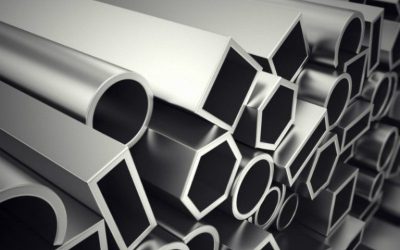

There are many different options in the design or the configuration of electrical grade aluminum bus bar. It is most often a solid bar, rod or a flat strip, but it can also be designed to be hollow. Typically, hollow designs are used with high current demands. It is important to realize that even a solid bus bar is not used as a structural component, even though aluminum alloys are often used in the type of an application.

The choice of the design or the shape of the bus bar is a factor of the amount of electrical current and the specific use conditions. In areas of use prone to mechanical vibrations, high humidity levels or the risk of extreme temperatures different designs and shapes will be more effective. The specific design of the bus bar is always selected to mitigate these other factors and to provide a consistent transfer of the electricity through the system.

Considerations

In addition to the shape and design requirements of the bus bar, it will also be important to choose the right alloy to provide the electrical conductivity required.

Different alloys offer different electrical conductivity rates. Other properties of the alloy may also come into play if the bus bar has to have a better machinability rating or the need for specific factors such as tensile strength, elongation or Brinell hardness values.